![]()

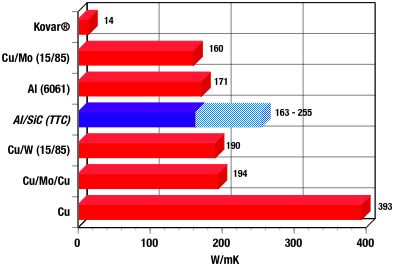

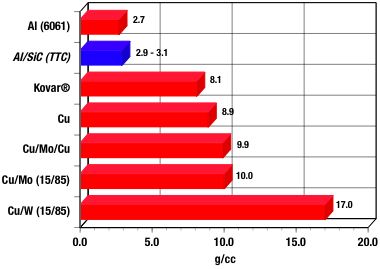

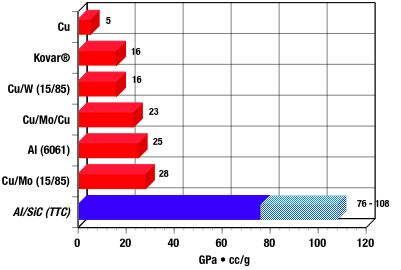

TTC's reinforced Al/SiC composites provide a unique combination of properties ideal for many electronic thermal management, packaging, and structural applications. The following data and information are provided to assist you in choosing the appropriate material for your application.

Note: Primex-Ultra Composites are for high performance applications requiring thermal conductivities in excess of 200 W/m•K, thermal expansion from 4 to 7 ppm/K, and Young's modulus up to 350 GPa

|

|

||||

|

|

185 (107) | 165 (95.3) | 225 (130.5) |

255

(146) |

|

|

7.0

(3.8) |

7.2

(4.0) |

5.8

(3.1) |

4.8

(2.6) |

|

|

3.00

(.108) |

2.94

(0.106) |

3.01

(0.109) |

3.10

(0.112) |

|

|

240

(35) |

235

(34) |

255

(38) |

300

(44) |

|

|

0.23 |

0.23 |

0.23 |

0.23 |

|

|

330

(49) |

330

(48) |

215 (32) |

210

(30) |

|

|

0.72

- 0.76 |

0.72

- 0.76 |

0.70

- 0.74 |

0.69 - 0.73 |

|

|

30

- 50 |

30

- 50 |

30

- 50 |

20-25 |

|

|

|

|

|

|

|

|

- |

- |

- |

- |

|

|

• |

|||

|

|

• |

|||

|

|

• |

• |

• |

• |

|

|

• |

• |

||

|

|

• |

• |

||

|

|

||||

|

|

• |

|||

|

|

• |

|||

|

|

||||

|

|

• |

![]()

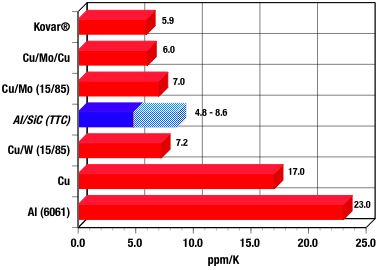

One key property to be considered in high performance design is the coefficient of thermal expansion or CTE. By matching the CTE's of the materials in an electronic assembly, stresses developed between them during power cycling are minimized. Lower stress means less fatigue in the bond joint between the assembly layers, resulting in a significant improvement in the long-term reliability of the system. With CTE values ranging from 4.8 to 8.6 ppm/K, TTC's PRIMEX™ Al/SiC composites provide an excellent match to most ceramic and semiconductor materials, including: Alumina, Aluminum Nitride, Beryllia, Silicon Nitride, Silicon, Gallium Arsenide, and Gallium Nitride.

![]()

![]()

![]()

PDF of Primex & Primex Cast Information

![]()

|

|

|

|

|

|

|

183

(106)

|

165

(92.5)

|

132

(76.3)

|

|

|

11.9

(6.6)

|

14.0

(7.8)

|

16.2

(9.0)

|

|

|

2.87

(0.104)

|

2.80

(0.101)

|

2.77

(0.100)

|

|

|

151

(21.9)

|

125

(18.1)

|

106

(15.4)

|

|

|

0.28

|

0.29

|

0.31

|

|

|

226

(32.7)

|

239

(33)

|

295

(42.7)

|

|

|

0.763

(0.17)

|

0.83

(0.18)

|

0.89

(0.19)

|

All data are nominal for F condition, data may vary with heat treatment and casting method.

![]()

All of TTC's PRIMEX Cast™ materials may be used for a variety of thermal management and structural applications. Please contact TTC for assistance in identifying the material and casting method that best meets your performance and volume requirements.

![]()

![]()

![]()

![]()

PDF of Primex & Primex Cast Information

The information set forth herein is based on technical data which TTC (Thermal Transfer Composites, LLC) believes to be reliable. Since conditions of use are outside TTC’s control, no warranties, express or implied, are made and no liabilities are assumed in connection with any use of this information. Materials must be tested under actual service conditions to determine their suitability for a particular purpose. Nothing herein is to be taken as a license to operate under or a recommendation to infringe any patents.

PrimexTM and Primex castTM are trademarks of Lanxide Technology Company, LP

Copyright © 2012 Thermal Transfer Composites, LLC.

Q:

What is Al/SiC?

A: Al/SiC is a metal matrix composite composed of silicon carbide particles and an aluminum alloy. As shown in this color enhanced micrograph the silicon carbide particles (blue) are surrounded by a continuous aluminum matrix (off-white). All of TTC's Al/SiC composites are isotropic and do not have an aluminum skin which can often result in non-isotropic behavior, i.e. bi-metalic deformation. In addition, TTC's composites do not suffer thermal cycle aging (TCA) effects. TCA occurs when materials are thermal cycled over continuous and/or long periods of time during which the filler material (e.g. SiC) and matrix (Al alloy) becomed decoupled, leading to a degradation of thermal conductivity, CTE control, and physical strength.

Q: Can Al/SiC be machined?

A: Yes, Al/SiC can be machined, however the type of machining process used will vary depending upon the SiC content. TTC's composites can be machined by EDM (electrodischarge machining), diamond tooling, water jet, and laser machining (on sections 1 mm or less).

Q: What types of surface metallizations or treatments can be applied to Al/SiC?

A: TTC's Al/SiC composites can be plated with nickel, gold, tin and copper. TTC provides plating solutions for all popular solder types including Au/Sn, Au/Si, and Au/Ge. TTC's plating has been certified for soldering to temperatures up to 450°C in air. TTC's PRIMEX™ and PRIMEXCast™ composites can also be anodized and chemical conversion coated (see surface treatments in design guidelines).

Q: What kind of attachment methods can be used to bond ceramic substrates, or organic printed wiring boards to Al/SiC?

A: Metallized ceramic substrates can be soldered to plated Al/SiC. Adhesives, epoxies, thermoplastics, or thermoset plastics can be used to bond organic printed wiring board cores to Al/SiC.

Q: Is Al/SiC hermetic?

A: Yes, all of TTC's Al/SiC materials are hermetic. However, hermetic bonds to metals or ceramics can only be made by using the proper combination of plating (on the Al/SiC) and solder.

Q: Is Al/SiC Isotropic?

A: Yes, the thermal and physical properties of TTC's Al/SiC materials are isotropic. However, some minor property orientation may be observed in PRIMEX Cast™ based materials that have shaped through secondary operations such as rolling or extrusion.![]()

![]()