![]()

Engineered for solving thermal management and structural problems in severe environments, TTC's Al/SiC components meet these challenges through cutting-edge composite technologies that combine the best properties of both metals and ceramics. This approach allows TTC to tailor the properties of the final product to meet multiple performance requirements, such as thermal expansion, weight, stiffness, and thermal conductivity without the compromises often associated with traditional material solutions.

![]()

Transforming engineered materials into innovative products is a TTC hallmark that sets it apart from the competition. TTC continues its leadership in design with two complimentary product lines that repeatedly exceed the most demanding customers' requirements.

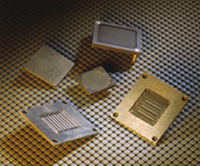

![]() components

are designed for systems requiring low to moderate thermal

dissipation through direct-contact

conduction cooling.

components

are designed for systems requiring low to moderate thermal

dissipation through direct-contact

conduction cooling.

Power Module Base Plates and Heat Sinks: The reliability of high performance IGBT and MOSFET power modules can be significantly improved by replacing standard copper base plates with PRIMECOOL™ base plates that closely match the thermal expansion of the ceramic substrates carrying the power die.

Microprocessor

Lids and Heat Spreaders:

In

microprocessor packaging applications considerable cost savings and substantial

package weight reduction can be realized through the replacement of copper/tungsten

and copper/molybdenum. In addition, ITM's PRIMECOOL™ Lids can be

provided with CTE values ranging from 6.8ppm/C to 16 ppm/C.

Printed Wiring Board Cores: PRIMECOOL™ PWB cores improve surface mount assembly reliability by minimizing thermal cycling and vibration fatique, as well as providing excellent thermal performance, while saving up to 70% of the weight of conventional metal cores.

Carriers and Hybrid Package Bases: PRIMECOOL™ carriers and package bases have demonstrated weight savings ranging from 33% to over 80%, while matching or exceeding the thermal performance of Cu/W and Fe/Ni alloy based components.

Electronic Chassis and Enclosures: PRIMECOOL™ chassis and enclosures have achieved weight savings of more than 45%, with improved dimensional stability over those manufactured from machined aluminum.

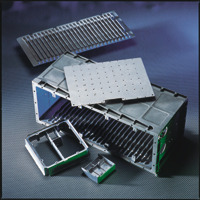

![]() components, designed

as rugged one-piece Al/SiC heat exchangers with internal pin or fin cooling

features, are offered for severe environment and mission critical applications.

TTC's PRIMEFLO I™ printed wiring board cores, power module heat sinks/base

plates and custom design heat sinks are found in numerous aerospace and

defense, high-end commercial applications.

components, designed

as rugged one-piece Al/SiC heat exchangers with internal pin or fin cooling

features, are offered for severe environment and mission critical applications.

TTC's PRIMEFLO I™ printed wiring board cores, power module heat sinks/base

plates and custom design heat sinks are found in numerous aerospace and

defense, high-end commercial applications.

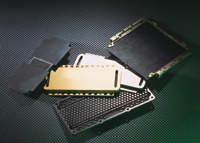

![]() components combine

the simplicity of the PRIMECOOL™ line with active cooling pin or

fin cooling features and are offered for applications where maximum performance,

design flexibility, and economy are required. In addition, unlike competing

Al/SiC designs from other suppliers, TTC's PRIMEFLO II™ components

have all Al/SiC pins, not molded on aluminum pins. TTC's PRIMEFLO II™

power module base plates and custom heat sinks are found in automotive,

traction (electric powered train) and stationary power system applications.

components combine

the simplicity of the PRIMECOOL™ line with active cooling pin or

fin cooling features and are offered for applications where maximum performance,

design flexibility, and economy are required. In addition, unlike competing

Al/SiC designs from other suppliers, TTC's PRIMEFLO II™ components

have all Al/SiC pins, not molded on aluminum pins. TTC's PRIMEFLO II™

power module base plates and custom heat sinks are found in automotive,

traction (electric powered train) and stationary power system applications.

![]()

![]()